ProductPRODUCT

Featured products

Contact Us

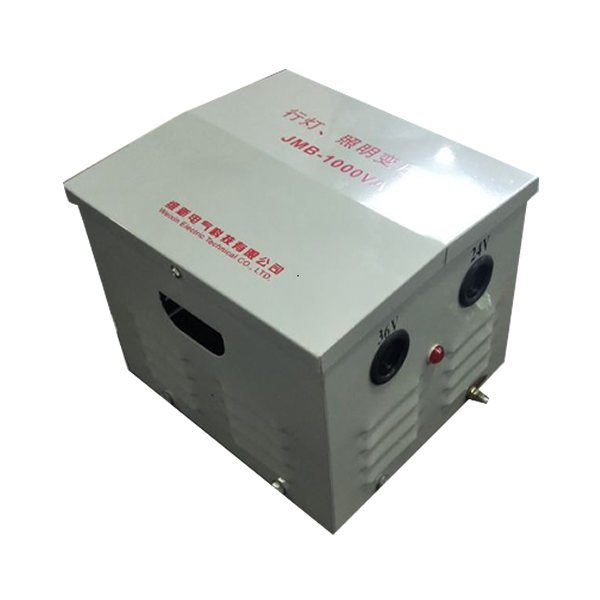

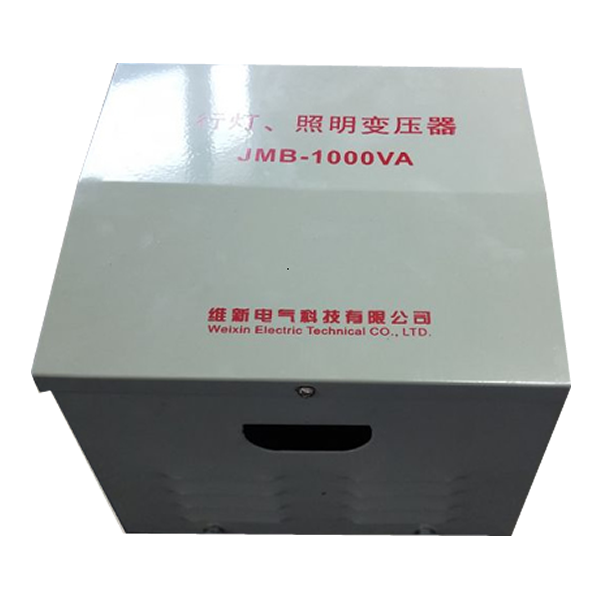

The JMB series lighting transformer is suitable for use as a local lighting power supply for machine tools and other equipment in circuits with a frequency of 50Hz and a voltage of 500V and below. The JMB series transformer consists of a BK series transformer and a protective casing. The casing has terminal posts on both sides for input power and load wiring, as well as grounding screws for grounding; The BZ type lighting transformer is composed of BK-50, BK-100 control transformers, LS3-2 type master switch, and protective housing. A fuse is installed on the master switch to protect the lighting circuit, and the power supply is provided from the dust-proof film at the end where the master switch is installed.

Material description of transformer:

① Iron core

We use brand new high-quality high silicon steel sheets, mainly made of 0.35 thick H18, H14, H12, Z11 high-quality silicon steel sheets. Based on the requirements and usage conditions of the guest room, we select the most suitable materials to achieve the best performance design of the transformer. (The conventional material is brand new high-quality silicon steel sheet).

② Wire rod

We use PEW, UEW, EIW, SEIW, FEAI enameled wire and glass fiber wrapped wire, with temperature resistance levels of F (155 ℃), H (180 ℃), HC (200 ℃), and C (220 ℃). (The conventional temperature resistance level is H-level 180 ℃).

③ Insulation material

Using high-temperature resistant insulation paper as the insulation material, it has multiple properties including high-temperature insulation, flame retardancy, and moisture resistance.

④ Wiring terminal block

Low power adopts terminal block, with beautiful appearance, excellent pressure resistance, temperature resistance, and flame retardant performance. High power uses high-quality copper bars.

⑤ Iron feet

Mainly using CNC bending cold plate, there are environmentally friendly electroplating options available, such as plating with colorful (golden), blue zinc (silver white), white zinc (ivory white), and surface anodizing (black).

Normal working conditions:

1. The upper limit of ambient air temperature shall not exceed+40 ℃:

2. The average temperature of the surrounding air for 24 hours shall not exceed+30 ℃:

3. The lower limit of ambient air temperature shall not be lower than -5 ℃:

4. Altitude: The altitude of the installation location shall not exceed 2000 meters

5. Atmospheric conditions: The relative humidity of the atmosphere should not exceed 50% when the surrounding air temperature is+40 ℃. Higher relative temperatures can occur at lower temperatures, with an average maximum relative humidity of 90% in the wettest month and an average minimum temperature of+25 ℃. Additionally, condensation on the product surface due to temperature changes should be taken into account

6. Pollution level: Pollution level is level three:

7. Installation category (overvoltage category): Installation category is Class III:

8. Power supply voltage: allowable deviation of power supply voltage ± 5%:

9. Installation conditions: Install in a place without severe vibration and impact vibration.

Scope of application:

Posts and telecommunications, shopping malls, elevators, hospitals, schools, printing, securities and other places that require normal voltage, as well as large and medium-sized industrial and mining enterprise workshops, some power supply and important equipment and single machine matching.